Most Starlight Image Intensified (I2) Night Vision products are light amplifying devices and consist of several main parts: an objective lens, an eyepiece, a power supply and an image intensifier tube.

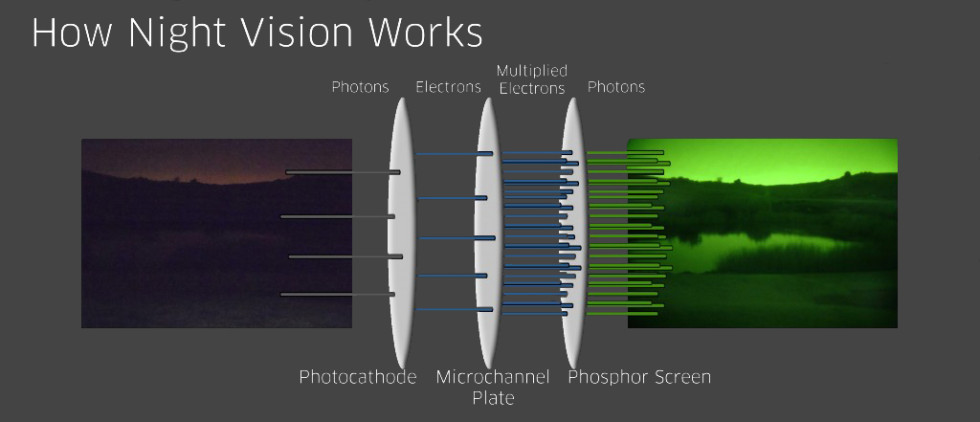

Light amplification technology allows small amounts of light energy, such as from moonlight or starlight, to be converted into electrical energy (electrons). These electrons multiply exponentially through electrical and chemical processes. They then bounce off of a phosphor screen, which converts the electrons back into photons, in order to display an impressive nighttime image even in total darkness.

In addition to traditional Green Color Phosphor image intensifier tube (IIT), there was a recent introduction of White Color Phosphor tubes, which allow users to view black and white images instead of traditional green and black.

In the night vision world “generation” reflects the level of technology used for a particular device. The higher the generation, the better performance you will get out of your night vision device.

Light Amplification

- Light amplification technology is also known as image enhancement. This technology relies on a special tube, called an Image Intensifier Tube, which collects and amplifies infrared and visible light. Basically, the tube converts photons into electrons and back again.

How it works:

- The optic’s conventional Objective Lens captures ambient and some near-infrared light.

- The gathered light is funneled to the Image Intensifier Tube. This battery-powered system outputs a high voltage of about 5,000 volts to the image-tube components.

- The light energy (photons) passes through the Photocathode, which converts them to electric energy (electrons).

- The electrons continue through the tube to the Microchannel Plate (MCP) where they are multiplied by a factor of thousands. The MCP is a tiny glass disc that has millions of microscopic holes (microchannels), made using fiber-optic technology. The MCP is contained in a vacuum with metal electrodes on either side. Each microchannel is about 45 times longer than it is wide. The travelling electrons are accelerated into the MCP as they hit the first electrode, hurtling them through the microchannels by the 5,000-volt burst being sent between the electrode pair. As the electrons pass through the microchannels, they cause thousands more electrons to be released in each channel in a process called Cascaded Secondary Emission. Basically, the original electrons collide with the sides of the channels, exciting atoms and causing other electrons to be released. The newly-released electrons also collide with the sides of the microchannels, creating a chain reaction of thousands more electrons being released. While only a few electrons entered the MCP, thousands leave it by time they make their way through. The microchannels are created at a slight angle (about 5-8 degree bias) to encourage electron collisions and reduce both ion and direct-light feedback from the phosphors on the output side.

- The electrons exit the Microchannel Plate and hit a screen coated with Phosphors. The electrons maintain their position in relation to the channel they passed through. Since they stay in the same alignment as the original photons that entered the tube, they provide a perfect image upon exiting. The energy of the electrons cause the phosphors to reach an excited state, releasing photons. The phosphors create the green image on the screen that characterizes modern night vision.

- The green image is viewed by the operator through the Ocular Lens. The ocular lens allows for the magnification and focus of the image.

Classification

The level of performance relates to Technology Generation. The higher the Generation number, the better the performance. Performance levels are largely based on the amount of available light necessary to produce a clear image.

- Generation 0 – The original night vision system created by the United States Army was first used in combat during the Battle of Okinawa in 1945 during World War II and later in the Korean War. It was first suited for individual use in the form of the M3 Carbine; an M2 Carbine fitted with a mount designed to accept an infrared sight, the T-120. Before then, Generation 0 systems were mounted on tanks. Gen0 systems rely on Active Infrared, meaning that a projection unit called an IR Iluminator is attached to the device. The unit projections a beam of near-infrared light in the same way a flashlight projections visible light. The near-infrared light is invisible to the naked eye and reflects off objects, bouncing back to the lens of the night vision device. Gen0 systems use an Anode in conjunction with a Cathode to accelerate the electrons. While revolutionary in its day, this approach of electron acceleration distorts the image and greatly decreases the life of the tube. This technology was quickly duplicated by hostile nations and allowed enemy combatants to easily see the projected infrared beam like a beacon. Generation 0 night vision is considered obsolete for modern tactical application.

- Generation 1 – The introduction of Passive Infrared marked the advent of Gen1 night vision devices. These are the “Starlight Scopes” of the 1960’s used during the Vietnam War. The most widely-issued Starlight Scopes were the AN/PVS-1 and AN/PVS-2. Generation 1 night vision devices use ambient light provided by the moon and stars to augment the normal amounts of reflected infrared in the environment and are built by connecting three image intensifier tubes in a series. The major innovation is that, unlike Gen0, Generation 1 units do not require a source of projected infrared light. Their main limitation is that they do not work well on cloudy or moonless nights. Gen1 systems use an Anode in conjunction with a Cathode, so like the previous Gen0, Gen1 units suffer from image distortion and short tube life. Many of the inexpensive night vision units offered on the market (including the Russian systems which are often mislabeled as higher generation) use Generation 1 technology. Crude by today’s standards, Generation 1 units can be considered “toys” and are not recommended for tactical application.

- Generation 2 – Developed in the 1970’s, Gen2 night vision systems mark a major improvement in image intensifier technology. Gen 2 units offer improved resolution and performance over the earlier Generation 1 and are considered to be much more reliable. Usability is greatly increased in that Gen2 systems can be made small enough for head-mounting; the first of which was the AN/PVS-5 (still in use today). The increase in sensitivity of Generation 2 night vision units is due to the addition of the Microchannel Plate to the image-intensifier tube. The MCP increases the number of electrons rather than simply accelerating the original ones, offering a significantly-less distorted and brighter image than the previous gen, while providing a 2,000 hour tube life. Generation 2 units are widely used in tactical applications today, with Gen2+ units offering images comparable with the later Gen3.

- Generation 3 – Generation 3 is the most current generation of night vision, developed in the 1980’s, and is widely issued and used by US warfighters and elite law enforcement units. The most widely recognized Gen3 units are the PVS-7 Night Vision Goggles and the PVS-14 Night Vision Monocular, though Gen3 tubes are present in many other units. There are no substantial changes in the underlying technology from Gen2, but Gen3 systems have even better resolution and sensitivity. This is because the Photocathode is made using Gallium Arsenide, which is extremely efficient in converting photons into electrons and enables detection of objects at greater distance under much darker conditions. The Microchannel Plate is also coated with an Ion Barrier to dramatically increase the life of the tube to 10,000 hours as demonstrated by actual testing and not extrapolation. Generation 3 night vision systems are considered to be the best option for today’s modern conflicts.

- Generation 4 – A strong debate rages in certain circles regarding the existence of Generation 4 night vision systems. The short answer is: yes, they do exist. However, the explanation as to why it is not in service is a bit more complicated. Development of Gen4 technology began in response to a request from the US Army in 1998 for a tube that had no ion barrier or protective coating on the Microchannel Plate. The new systems would be dubbed “Gen4” and were based on preliminary tests revealing that a filmless tube would increase performance by 20%. The problem is the cost with which this “upgrade” came. Testing revealed immediate degradation of the tube because there was, now, no protection of the Photocathode from the harmful ions generated during normal tube operations. These Gen4 tubes were, also, not meeting the 10,000 hour tube life requirement of standard Gen3 devices.

Exelis (formerly ITT Night Vision) and Litton, the two foremost manufacturers of PVS-14’s, began development of their Gen4 systems to meet the Army’s new Omni V Procurement Contract. During their development process, Exelis found that the answer was not to remove the protective film, but to thin it. This new microfilm (10,000 times thinner than a human hair) provides the protection of the tube needed to meet the 10,000 hour tube life requirement while offering Gen4 performance. This new tube has become the system by which all other night vision units are judged. But, since it still contains a protective film, it cannot, honestly, be classified as Generation 4 (even though it provides better all-around performance). So, Generation 4 technology does exist, but it is not practical for field use.

- Generation 3 Pinnacle – PINNACLE© is a proprietary thin film technology, only available from Exelis (formerly ITT Night Vision) that represents an enhancement to Generation 3 image intensifier technology. To understand PINNACLE© it is important to understand film technology in Gen3 tubes and why it is needed. Light energy, or “photons” strikes the photocathode (the first surface in a Gen3 tube) causing electrons to be emitted out the other side, towards the Microchannel Plate (MCP). When they strike, they knock even more electrons out of other atoms, causing them to be positively charged (positive ions). The electrons pass through the MCP, continually multiplying and get converted back into photons for your eye to see as they pass through the phosphor screen. But, the positive ions created at the MCP travel in the opposite direction of the electrons and head back to the photocathode, striking it with significant force which can lead to damage. Suffice to say, Gen3 tubes are more sensitive to this damage than Gen2 and require protective film barrier of Aluminum Oxide to get the life needed out of the tube. The Aluminum Oxide film is placed over the MCP to absorb the positive electrons before they can travel back to the photocathode to damage it. However, this film only allows about 50% of the electrons through, reducing the sensitivity, and represents the standard Gen3 tube. The government requested Gen4, the goal of which was to remove the film to allow 100% transfer. However, this severely cut the tube life and was deemed unacceptable. So, Exelis produced a tube with a thinner film that would allow more transfer of electrons than the standard Gen3 tube. Since it also allows more transfer of the damaging positive ions, Exelis reduces the electrostatic fields around the MCP/ Photocathode. So, in laymen’s terms, much more light is let through. This, however, causes another problem.

On its own, a thin-filmed tube lets in too much light, so excessive light such as street lights and head lights are a big problem. So, as part of the Gen3 Omni VII package, PINNACLE© tubes contain an advanced autogated power supply, improved MCP hole size, a more sensitive photocathode, and other improvements which eliminate the temporary blindness caused by exposure to light too bright for the night vision device and drastically reduce the halo effect around distant light sources. The user can stay on mission and in the fight because his/her vision is not bloomed out. Initially, PINNACLE© tubes were only put into MILSPEC units. Night Quest and Night Enforcer units did not get PINNACLE© tubes. Eventually, Exelis stopped making the dual battery configuration PVS-14 and consolidated their commercial and law enforcement lines into the Night Enforcer line. At this time, the Night Enforcer used a standard Exelis Gen3 Autogated tube, while the MILSPEC AN/PVS-14 got PINNACLE© tubes. The Night Enforcers built during this period can be identified by their label which has the model number “NEPVS-14-11.” These Night Enforcers had the same body housing and features of the AN/PVS-14, minus the PINNACLE© tube. It wasn’t long before Exelis consolidated production yet again and made the decision to only produce Gen3 PINNACLE© Autogated tubes and put them in all their PVS-14′s. This really only affected the Night Enforcer line and represents the Night Enforcer model available today. The latest and greatest Night Enforcer PVS-14 has a label that reads: “NEPVS-14-17.” This is how to identify a PINNACLE© Night Enforcer. Of course, all current production AN/PVS-14′s have had PINNACLE© tubes since they were released. The difference in item numbers is critical because there were a lot of tactical gear retailers that offered PVS-14′s along with other gear.

PERFORMANCE ATTRIBUTES

While organization by Generation is a classifiable way of categorizing night vision devices, individual units are evaluated by their specific performance attributes. These are divided into three main areas.

- Sensitivity, or Photo-response, is the image tube’s ability to detect available light and is usually measured in microamperes per lumen (uA/lm). The latest generation night vision devices have excellent sensitivity and do not require added IR illumination. Some manufacturers, who use lesser-quality tubes, will add IR illuminators to their products to “boost” the perceived performance in low light areas. These units are to be avoided for any tactical work since they require an IR illuminator to achieve acceptable performance. The IR light can be detected by adversaries using night vision and can compromise the operator’s position.

- Signal-to-Noise plays a key role in night vision performance. It is the unit’s ability to transfer a strong signal from input to output and is usually referenced as a ratio, 19:1 for example. Signal to noise is the role of the Micro-channel Plate in Gen2 and 3 night vision systems.

- Resolution is the unit’s ability to resolve detail in the image. Measured in line pairs per millimeter (lp/mm), higher resolution produces a cleaner image. Some manufacturers put magnified optics in their systems to give the illusion of higher-resolving systems. However, this sacrifices field-of-view and can give the operator a disproportionate idea of their environment if they are relying on the night vision unit for navigation purposes. Some units give the option of higher magnification, but it is not necessary for effective function of the system. The highest possible resolution is required for accurate target discrimination aiding in preventing blue-on-blue and blue-on-white incidents.

Detection Ranges

This chart is based on night vision systems with a 1x lens. Recognition range will increase when greater magnification is used.

Night Vision Characteristics

Textures, Light & Dark

- Objects that appear light during the day, but have a dull surface may appear darker than (normally) dark objects with highly reflective surfaces through night vision units. For example: a shiny dark-colored jacket may appear brighter than a light-colored jacket with a dull surface.

Depth Perception

- Night vision does not present normal depth perception. The naked eye has an approximate 190 degree field of view. Most night vision goggles have only a 40 degree field of view. This is somewhat tempered by the advent of the night vision monocular which keeps one eye free, reducing the tunnel-like view. This greatly increases overall depth perception and situational awareness since the unaided eye can maintain peripheral vision. Even so, depth perception is somewhat limited, which can hamper the operator’s ability to navigate cluttered terrain and perform simple tasks that require hand/eye coordination. Distance estimation is also degraded, requiring much training for high speed driving while using night vision.

Fog and Rain

- Night vision is very responsive to reflective ambient light; therefore, the light reflecting off fog or heavy rain causes much more light to go toward the night vision unit and may degrade its performance.

Honeycomb

- This is a faint hexagonal pattern which is the result of the manufacturing process.

Black Spots

- A few black spots throughout the image area are inherent characteristics of all night vision technology. These spots remain constant and should not increase in size or number.

An in-depth article on How Night Vision Works can also be found here

Gen 1+ IIT

First generation devices work by amplifying existing light by several thousand times. Using an alternating photocathode/anode conversion between light and electrons, the cascading approach utilizes progressively increased voltages to increase electron speed and, consequently, allows you to see clearly in the dark. These units provide bright, fully visible images at a low cost, which makes them a popular choice for boating, wildlife observation, and home security.

CORE IIT

Thanks to the latest advancements in electro optical manufacturing, Armasight redefines affordable high performance night vision with CORE™ (Ceramic Optical Ruggedized Engine) Image Intensifier technology. Unlike Gen 1 Image intensifier tubes that are fragile by a virtue of being made from glass, CORE™ IITs are made just like Gen 2 and Gen 3 by fusing metal alloys with ceramic compounds. CORE™ technology is based on durable elements and allows tight component stacking, resulting in image tubes that are exceptionally shockproof and vibration resistant. Robust packaging envelop lacks easy-to-break protrusions common in Gen 1 tubes and allows for streamline design of lighter, compact and more reliable night vision devices. CORE™ platform offers best in class resolution with 60-70 lp/mm, increased photocathode sensitivity level in upwards of 400μA/lm providing image quality in prevalent ambient light condition rivaling high-end Gen 2 image tubes.

The main difference between a 1st and a 2nd generation unit is the addition of a micro-channel plate, commonly referred to as a MCP. The MCP works as an electron amplifier and is placed directly behind the photocathode. The MCP consists of millions of short parallel glass tubes. When the electrons pass through these short tubes, thousands more electrons are released. This extra process allows 2nd generation units to amplify the light many more times than 1st generation giving you a brighter and sharper image.

These image intensifiers vary in performance and specifications and are therefore divided into categories accordingly:

ATN Night Vision Devices:

Gen 2+ Standard Image Intensifier features:

- Photo Cathode type: Multi-Alkali

- Resolution from 40 to 45 lp/mm

- Signal-to-Noise Ratio from 12 to 20

- 5,000+ hour tube life

Gen 2+ CGT. The CGT type of Image Intensifier tubes are engineered for significantly enhanced performance over current 2nd generation IITs. The CGT IIT is a Multi-Alkali compact 18mm format MCP Image Intensifier.

- Photo Cathode type: Multi-Alkali

- Resolution from 45 to 54 lp/mm

- Signal-to-Noise Ratio from 16 to 22

- 10,000-hour tube life

Gen 2+ HPT. HPT tubes are an upgrade of the CGT Generation tube. They are a Multi-Alkali compact 18mm format MCP Image Intensifier. The HPT tube increases sensitivity, resolution, Signal-to-Noise Ratio (SNR), and the Modulation Transfer Function (MTF). These improvements produce an exceptional image clarity and brightness. Most HPT specifications typically are equivalent to standard 3rd generation.

- Photo Cathode type: Multi-Alkali

- Resolution from 55 to 72 lp/mm

- Signal-to-Noise Ratio from 16 to 24

- 10,000-hour tube life

Armasight Night Vision Devices:

Gen 2+ SD Standard Definition Second Generation tubes have a micro channel plate (MCP) electron amplifier, as well as a multi-alkaline photocathode with a built-in power supply. Typically, resolution ranges from 45 to 51 lp/mm and the Signal-to-Noise Ratio ranges from 15 to 22.

Gen 2+ ID Improved Definition. Our Gen 2+ ID image intensifier tubes are engineered for significantly enhanced performance over current 2nd Generation IITs. The Gen 2+ ID IIT is a compact, Multi-Alkali, 18mm format, proximity-focused MCP-based image intensifier. Resolution ranges from 47 to 54 lp/mm and the Signal-to-Noise Ratio typically ranges from 15 to 21.

Gen 2+ HD High Definition. Our Gen 2+ HD tubes are an upgraded version of the Gen 2+ ID tube. Most HD specifications approximate a baseline similar to 3rd generation image intensifier tubes. The Gen 2+ HD tubes include a multi-alkali photocathode, a resolution range of 55 to 72 lp/mm, and typically, a Signal-to-Noise Ratio of 15 to 23.

By adding a sensitive chemical, gallium arsenide to the photocathode a brighter and sharper image has been achieved over 2nd generation units. An ion barrier film was also added to increase tube life.

These image intensifiers vary in performance and specifications and are therefore divided into categories accordingly:

Exelis (formerly ITT Night Vision):

Gen 3P The industry leading Exelis Pinnacle™ image tubes utilize a gated power supply providing truly outstanding performance in high-light or light-polluted areas, such as urban environments. The Pinnacle™ tube with gated power supply minimizes any “halo” effects. “Halo” is often associated with using night vision devices in an urban area where random street lights are often an issue with early Generation Night Vision devices.

Exelis is one of two factory manufacturers of image intensifier tubes in the United States and the largest producer of night vision in the world. They provide the standard issue AN/PVS-14 for the U.S. Army, Navy, and Air Force. Exelis Pinnacle™ tubes feature a thinner film than their L3 Counterparts. This allows them to capture and process more light, providing the user with a brighter image. But, the thin-film means they do not hold up as well to weapon recoil. These tubes are weapons rated for 5.56x45mm NATO.

*Pinnacle is a registered trademark of Exelis Night Vision

L3 Warrior Systems:

Gen 3L3 These tubes meet the current U.S. Military OMNI VIII contract specs and, provide some of the cleanest images available. L3 is one of two factory manufacturers of Gen3 image intensifier tubes in the United States. They provide the majority of goggle systems used by U.S. Special Operations Forces. L3 tubes are designed to be weapons-rated and feature a thicker film to protect them from recoil shock. These tubes are weapons rated for 5.56x45mm NATO, 7.62x39mm, 6.8 SPC, and 300 Blackout.

ATN Night Vision Devices:

Gen 3 Standard image intensifier tubes are of the highest quality. They have a micro channel plate, GaAs photocathode, and a completely self-contained integral high-voltage power supply. These 3rd Generation tubes provide a combined increase in resolution, signal to noise and photosensitivity over tubes with a multi-alkali photocathode. Generation 3 is the standard for the USA military.

- Photo Cathode type: Gallium Arsenide

- Resolution 64 lp/mm

- Signal-to-Noise Ratio 22 Typical

- 10,000-hour tube life

Gen 3A Premium image intensifier tubes are handpicked to provide the highest quality and specifications available in our 3rd Generation line. They have a micro channel plate, GaAs photocathode, and a completely self-contained integral high-voltage power supply.

- Photo Cathode type: Thin Film GaAs

- Resolution from 64 to 72 lp/mm

- Signal-to-Noise Ratio 26 Typical

- 10,000-hour tube life

Gen 3P ATN Night Vision units with the 3P designation use Exelis (formerly ITT Night Vision) Pinnacle™ Image Intensifier tubes. The industry leading Exelis Pinnacle™ image tubes utilize a gated power supply providing truly outstanding performance in high-light or light-polluted areas, such as urban environments. The Pinnacle™ tube with gated power supply minimizes any “halo” effects. “Halo” is often associated with using night vision devices in an urban area where random street lights are often an issue with early Generation Night Vision devices. Night Vision units with Pinnacle™ tubes have a resolution of 64-72 lp/mm and a typical signal to noise ratio of 26. All Night Vision devices utilizing Pinnacle™ Image Intensifier tubes come with Exelis data record sheet. Units with Pinnacle™ tubes are not available for export. A signed export compliance and end use statement is required prior to shipping of these units.

*Pinnacle is a registered trademark of Exelis Night Vision

- Photo Cathode type: Gallium Arsenide

- Resolution from 64 to 72 lp/mm

- Signal-to-Noise Ratio: 25-30

- 10,000-hour tube life

Gen 3 Filmless Auto gated / Filmless inverting image intensifier tubes (sometimes referred to as Gen 4 IITs) improve night operational effectiveness for users of night vision goggles and other night vision devices. The filmless micro channel plate provides a higher signal-to-noise ratio than standard 3rd Gen. IITs, resulting in better image quality under low-light conditions. An auto gated power supply further improves image resolution under high light conditions and a reduced halo effect that minimizes interference from bright light sources. The reduced Halo maximizes the effectiveness of the Night Vision device in dynamic lighting conditions such as those experienced, for example, in night operations in urban areas.

- Photo Cathode type: Filmless GaAs

- Resolution from 64 to 72 lp/mm

- Signal-to-Noise Ratio from 25 to 30

- Auto gated power Supply

- 10,000-hour tube life

Armasight Night Vision Devices:

Gen 3 Bravo 3rd Generation image intensifier tubes deliver high quality night vision images. Generation 3 is the standard for the United States military. They include a Gallium Arsenide (GaAs) photocathode, a resolution range of 57 to 64 lp/mm, and a Signal-to-Noise Ratio of 16 to 30.

Gen 3 Alpha These IITs are hand-picked to provide the highest quality available in our Gen 3 line. They include a micro channel plate, Thin Film GaAs photocathode, and a completely self-contained high-voltage power supply. A resolution of 64 to 72 lp/mm and a Signal-to- Noise Ratio of 16 to 30 is typical.

Gen 3P Exelis (formerly ITT Night Vision) Pinnacle™ These Night Vision units are designed around the Gen 3P Exelis Pinnacle* image intensifier tubes. These industry-leading tubes utilize a gated power supply that provides outstanding auto gated performance. The Pinnacle tube minimizes the “halo” effect often associated with light interference caused by sources of bright light. They include Gallium Arsenide photocathodes, a resolution range of 64 to 72 lp/mm, and a Signal-to-Noise Ratio of 16 to 30.

*Pinnacle is a registered trademark of Exelis Night Vision

FLAG Armasight’s FLAG (FilmLess AutoGated) image intensifier tubes (sometimes referred to as Gen 4 IITs) improve operational effectiveness for night vision users. The filmless micro channel plate provides a higher signal-to-noise ratio than standard Gen 3 IITs, resulting in better image quality in low-light conditions and minimizing the “halo” effect often associated with light interference caused by street lights and other sources of bright light. These units include Filmless GaAs photocathodes, an auto gated power supply, a Resolution that ranges from 64 to 72 lp/mm and a Signal-to-Noise Ratio of 16 to 30.

Somewhat recent developments in night vision technology, White Phosphor Image Intensifier Tubes (IITs) replace the regular phosphor screens with white phosphor in order to offer black and white image instead of customary green. Such displays appear remarkably more natural and provide clearer details, better contrast, and more distinct shapes and shadows.

ATN Night Vision Devices:

Gen 2+ WPT The majority of the WPT™ performance characteristics are on par or better than the latest Gallium Arsenide based image intensifier tubes. WPT™ specifications include typical resolution of 60 lp/mm (with some over 74 lp/mm) and Signal-to-Noise figures as high as 25.

Armasight Night Vision Devices:

Gen 2+ QS “Quick Silver” Gen 2+ IITs are characterized by high-contrast, white phosphor screens that offer black and white displays, which provide clearer details, better contrast, and more distinct shapes and shadows. They include a multi-alkali photocathode, a Resolution range of 47 to 54 lp/mm, and a Signal-to-Noise Ratio of 15 to 23.

Gen 3 “Ghost” “Ghost” White Phosphor IITs are characterized by high-contrast, white phosphor screens that offer black and white displays, which provide clearer details, better contrast, and more distinct shapes and shadows. They include a micro channel plate, GaAs photocathode, and a completely self-contained, high-voltage power supply. They have a Resolution range of 47 to 57 lp/mm, and a Signal-to-Noise Ratio of 16 to 30.

Automatic Brightness Control (ABC)

- An electronic feature that automatically reduces voltages to the Micro channel Plate to keep the image intensifier’s brightness within optimal limits and protects the tube. The effect of this can be seen when rapidly changing from low-light to high-light conditions; the image gets brighter and then, after a momentary delay, suddenly dims to a constant level.

Auto-Gated Power Supply

- When the power supply is “Auto-Gated,” it means the system is turning itself on and off at a very rapid rate. This, combined with a thin film attached to the Micro channel plate (an ion barrier) reduces blooming. While “blooming” can be noticeably less on systems with a thin film layer, systems with thicker film layers can be perfectly acceptable depending on the end user’s application. Deciding which night vision goggle is better should not be based solely on blooming.

Black Spots

- These are common blemishes in the image intensifier of the NVD or can be dirt or debris between the lenses of the NVG. Black spots that are in the image intensifier do not affect the performance or reliability of a night vision device and are inherent in the manufacturing processes. Every night vision image intensifier tube is different.

Bright Spots

- These can be defects in the image area produced by the NVG. A flaw in the film on the Micro channel plate causes this condition. A bright spot is a small, non-uniform, bright area that may flicker or appear constant. Bright spots usually go away when the light is blocked out and are cosmetic blemishes that are signal induced.

Biocular

- Viewing a single image source with both eyes (example: watching a television set).

Binocular

- Viewing a scene through two channels; i.e. one channel per eye.

Blooming

- Loss of the entire night vision image, parts of it, or small parts of it, due to intensifier tube overloading by a bright light source. Also, known as a “halo” effect, when the viewer sees a “halo” effect around visible light sources. When such a bright light source comes into the night vision device’s view, the entire night vision scene, or parts of it, becomes much brighter, “whiting out” objects within the field of view. Blooming is common in Generation 0 and 1 devices. The lights in the image to the right would be considered to be “blooming”.

Bright-Source Protection (BSP) – Highlight Cut-Off

- An electronic function that reduces the voltage to the photocathode when the night vision device is exposed to bright light sources such as room lights or car lights. BSP protects the image tube from damage and enhances its life; however, it also has the effect of lowering resolution when functioning except for the Pinnacle Auto gated Units which maintain the systems resolution.

Boresighting

- The alignment of a weapon-aiming device to the bore of the weapon. See also Zeroing.

C-Mount

- A standard still and video camera lens thread size for mounting to the body of a camera. Usually 1/2″ or 3/4″ in diameter.

COMSPEC (Commercial Specification)

- A term used to describe image tube quality, testing and inspection done by the original equipment manufacturer (OEM).

Chicken Wire

- An irregular pattern of dark thin lines in the field of view either throughout the image area or in parts of the image area. Under the worst-case condition, these lines will form hexagonal or square wave-shape lines.

Daylight Lens Cover

- Usually made of soft plastic or rubber with a pinhole that allows a small amount of light to enter the objective lens of a night vision device. This should be used for training purposes only, and is not recommended for an extended period of time. Near field focus only useable in this fashion.

Daylight Training Filter

- A glass filter assembly designed to fit over the objective lens of a night vision device. The filter reduces light input to a safe (night-time) level, allowing safe extended daytime use of the night vision device.

Diopter

- The unit of measure used to define eye correction or the refractive power of a lens. Usually, adjustments to an optical eyepiece accommodate for differences in individual eyesight. Most Exelis systems provide a +2 to -6 Diopter range.

Distortion

- There are two types of distortion found in night vision systems. One type is caused by the design of the optics, or image intensifier tube, and is classical optical distortion. The other type is associated with manufacturing flaws in the fiber optics used in the image intensifier tube.

- Classical Optical Distortion: Classical optical distortion occurs when the design of the optics or image intensifier tube causes straight lines at the edge of the field of view to curve inward or outward. This curving of straight lines at the edge will cause a square grid pattern to start to look like a pincushion or barrel. This distortion is the same for all systems with the same model number. Good optical design normally makes this distortion so low that the typical user will not see the curving of the lines.

- Fiber Optics Manufacturing Distortions: Two types of fiber optics distortions are most significant to night vision devices: S-distortion and shear distortion:

- S-Distortion: Results from the twisting operation in manufacturing fiber-optic inverters. Usually S-distortion is very small and is difficult to detect with the unaided eye.

- Shear Distortion: Can occur in any image tube that uses fiber-optic bundles for the phosphor screen. It appears as a cleavage or dislocation in a straight line viewed in the image area, as though the line were “sheared”.

Equivalent Background Illumination (EBI)

- This is the amount of light you see through a night vision device when an image tube is turned on but no light is on the photocathode. EBI is affected by temperature; the warmer the night vision device, the brighter the background illumination. EBI is measured in lumens per square centimeter (lm/cm2). The lower the value the better. The EBI level determines the lowest light level at which an image can be detected. Below this light level, objects will be masked by the EBI.

Edge Glow

- There is a defect in the image area of the NVG. Edge glow is a bright area (sometimes sparkling) in the outer portion of the viewing area.

Emission Point

- A steady or fluctuating pinpoint of bright light in the image area that does not go away when all light is blocked from the objective lens. The position of an emission point within the field of view will not move. If an emission point disappears or is only faintly visible when viewing under brighter nighttime conditions, it is not indicative of a problem. If the emission point remains bright under all lighting conditions, the system needs to be repaired. Do not confuse an emission point with a point of light source in the scene being viewed.

Eye Relief

- The distance a person’s eyes must be from the last element of an eyepiece in order to achieve the optimal image area.

Field-of-View

- The diameter of the imaged area when viewed through an optic

Figure of Merit (FOM)

- Image Intensification tube specification designation, calculated on line pair per mm x signal to noise.

Fixed-Pattern Noise (FPN)

- A faint hexagonal (honeycomb) pattern throughout the image area that most often occurs under highlights conditions. This pattern is inherent in the structure of the Micro channel plate and can be seen in virtually all Gen 2 and Gen 3 systems if the light level is high enough.

Footlambert (fL)

- A unit of brightness equal to one foot-candle at a distance of one foot.

Gain

- Also called brightness gain or luminance gain. This is the number of times a night vision device amplifies light input. It is usually measured as tube gain and system gain. Tube gain is measured as the light output (in fL) divided by the light input (in fc). This figure is usually expressed in values of tens of thousands. If tube gain is pushed too high, the tube will be “noisier” and the signal-to-noise ratio may go down. U.S. military Gen 3 image tubes operate at gains of between 20,000 and 45,000. On the other hand, system gain is measured as the light output (fL) divided by the light input (also fL) and is what the user actually sees. System gain is usually seen in the thousands. U.S. military systems operate at 2,000 to 3,000. In any night vision system, the tube gain is reduced by the system’s lenses and is affected by the quality of the optics or any filters. Therefore, system gain is a more important measurement to the user.

Gallium Arsenide (GaAs)

- The semiconductor material used in manufacturing the Gen 3 photocathode. GaAs photocathodes have a very high photosensitivity in the spectral region of about 450 to 950 nanometers (visible and near-infrared region).

Generations

- Two technologies are referenced as night vision; image intensification and thermal imaging (see definitions). Because of cost and the fact that image intensifier scenes are easier to interpret than thermal (thermal images show targets as black or white – depending upon temperature – making it more difficult to recognize objects), the most widely used night vision aid in law enforcement is image intensification (l²) equipment. To date, there have been four generations of l² devices, identified as Gen 0, Gen 1, Gen 2, and Gen 3. Developmental laboratory work is ongoing, and the U.S. military may designate the resulting as Gen 4. However, no definition for Gen 4 presently exists.

Halo

- Halo is the circular region around a bright light that appears “brighter” – It’s caused by elastic collisions of electrons with the MCP surface which subsequently then bounce off and down another hole. Halo’s are the same size all over the screen and the size is dictated by the distance between the photocathode and the MCP. Basically, it’s the round circle around lights when you look at them with Night Vision and it’s generally used as an indication that you’re looking at something that’s too bright.

Highlight Shutoff

- An image intensifier protection feature incorporating a sensor, microprocessor and circuit breaker. This feature will turn the system off during periods of extreme bright light conditions.

Interpupillary Adjustment

- The distance between the user’s eyes (pupils) and the adjustment of binocular optics to adjust for differences in individuals. Improperly adjusted binoculars will display a scene that appears egg-shaped or as a reclining figure-8.

Interpupillary Distance

- The distance between the user’s pupils (eyeball centers). The 95th percentile of US military personnel falls within the 55 to 72mm range of IPD.

IR Illuminator

- Many night vision devices incorporate a built-in infrared (IR) diode that emits invisible light or the illuminator can be mounted on to it as a separate component. The unaided eye cannot see IR light; therefore, a night vision device is necessary to see this light. IR Illuminators provide supplemental infrared illumination of an appropriate wavelength, typically in a range of wavelengths (e.g. 730nm, 830nm, 920nm), and eliminate the variability of available ambient light, but also allow the observer to illuminate only specific areas of interest while eliminating shadows and enhancing image contrast.

IR Laser

- High-power devices providing long-range illumination capability. Ranges of several thousand meters are common. Most are not eye-safe and are restricted in use. Consult FDA CFR Title 21 for specific details and restrictions.

IR (Infrared)

- Area outside the visible spectrum that cannot be seen by the human eye (between 700 nanometers and 1 millimeter). The visible spectrum is between 400 and 700 nanometers.

ITAR (International Traffic in Arms Regulations)

- ITAR represents a set of US Government regulations that control the export of defense-related materials, articles, and services on the United States Munitions List. These regulations implement the provisions of the Arms Export Control Act, and are described in Title 22 (Foreign Relations), Chapter I (Department of State), and Subchapter M of the Code of Federal Regulations. The Department of State Interprets and enforces ITAR. Its goal is to safeguard US National Security and further US Foreign Policy objectives. Basically, ITAR dictates that any defense related items (including Night Vision Equipment and IR Equipment) cannot be exported from the United States in any way, without express permission from the US Department of State. Failing to follow ITAR will result in felony charges which can lead to heavy fines and/or prison sentences.

LED (Light-Emitting Diode)

- LED’s are electronic light sources based on the semiconductor diode. When the diode is forward biased, electrons recombine with holes, releasing energy in the form of light. This is called Electroluminescence. The color of the light is determined by the energy gap of the semiconductor. LED’s have many advantages over traditional incandescent light sources including lower energy consumption, longer lifetime, more robustness, smaller size, and faster switching.

lp/mm (Line Pairs per Millimeter)

- Units used to measure image intensifier resolution. Usually determined from a 1951 U.S. Air Force Resolving Power Test Target. The target is a series of different-sized patterns composed of three horizontal and three vertical lines. A user must be able to distinguish all the horizontal and vertical lines and the spaces between them. Typically, the higher the line pair, the better the image resolution. Generation 3 tubes generally have a range of 64 – 72 lp/mm, although line pair measurement does not indicate the generation of the tube. Some Generation 2+ tubes measure 28-38 lp/mm, (Gen 2 SHP at 54-59 lp/mm typically), while a Generation 1+ tube may have measure at 40 lp/mm.

Lumen

- Denotes the photons perceptible by the human eye in one second.

Monocular

- A single channel optical device.

NATO-STANAG

- Term for the North Atlantic Treaty Organization STANdard AGreement. This can be described as an international MILSPEC

mA/W (Milliamps per Watt)

- The measure of electrical current (mA) produced by a photocathode when exposed to a specified wavelength of light at a given radiant power (watt).

MCP (Microchannel Plate)

- A metal-coated glass disk that multiplies the electrons produced by the photocathode. An MCP is found only in Gen 2 or Gen 3 systems. MCPs eliminate the distortion characteristic of Gen 0 and Gen 1 systems. The number of holes (channels) in an MCP is a major factor in determining resolution. Exelis Industries’ MCPs have 10.6 million holes or channels compared to the previous standard of 3.14 million.

Microwatts (uW)

- A microwatt is equal to one millionth of a watt. A watt is a derived unit of power in the International System of Units (SI) and measures the rate of energy conversion. One watt is equivalent to 1 joule of energy per second.

Mil-Dots

- The Mil-Dot reticle was designed around the unit of measurement called the miliradian. The dots of a mil-dot reticle allow the shooter to estimate range to a target of a known size, hold over targets with the mil-dots as a reference, and give a recognizable lead for moving targets. The US Army equates each mil to 3.375 MOA while the US Marines equate it to 3.438 MOA. The practical application has become one mil= 3.5 MOA. The Mil-Dot reticle is employed by placing the reticle over the target and aligning one end of the target to the flat of the reticle. The number of Mil-Dots are counted to provide an accurate reading.

Milliradians (mrad)

- A unit of measurement used to determine the divergence of a laser beam. The miliradian is equal to 0.001 radians and corresponds to an error of 1 meter at 1,000 meters.

Milliwatts (mW)

- A milliwatt is equal to one thousandth of a watt. A watt is a derived unit of power in the International System of Units (SI) and measures the rate of energy conversion. One watt is equivalent to 1 joule of energy per second.

MOA (Minute Of Angle)

- Commonly used in the shooting world as a point of reference, a Minute Of Angle is 1.047 inches at 100 yards. Normal shooter application uses the simplified 1” at 100 yards. For perspective, the difference between using the exact 1.047 and 1” is 0,47” at 1,000 yards. So, if a reticle has a 1 MOA dot, the dot would cover 1” at 100 yards. MOA is also relative to the click adjustments on scopes and iron sights. Scopes with 1/4MOA clicks would require 4 clicks to shift the bullet impact 1MOA (1”) at 100 yards. The same adjustment would move the bullet impact 1MOA at 200 yards, which is 2 inches. A simple way to calculate MOA at ranges less than 100 yards is to use the 100 yard adjustment and doubling the number of clicks for 50 yards and doubling again for 25 yards. For example, if a scope has ½ MOA click adjustments, it will require 2 clicks to move the bullet 1” at 100 yards, 4 clicks to move the impact 1” at 50 yards and 8 clicks to move it 1” at 25 yards.

Nanometer (nm)

- A unit of length in the metric system equal to one billionth of a meter. Nanometers are the most common unit used to describe the manufacturing technology used in the semiconductor industry and the most common unit to describe the wavelength of light.

Near-Infrared

- The shortest wavelengths of the infrared region, nominally 750 to 2,500 nanometers. Also see How Thermal Imaging and Infrared Technology Works.

NSN (National Stock Number)

- 13-digit code identifying all ‘standardized material items of supply’ as they have been recognized by the United States Department of Defense. National Stock Numbers have come to be used in all NATO countries pursuant to the NATO Standardization Agreements (STANAGs).

Photocathode

- The input surface of an image intensifier tube that absorbs light energy (photons) and in turn releases electrical energy (electrons) in the form of an image. The type of material used is a distinguishing characteristic of the different generations.

Photocathode Sensitivity

- Photocathode sensitivity is a measure of how well the image intensifier tube converts light into an electronic signal so it can be amplified. The measuring units of photocathode sensitivity are micro-amps/lumen (µA/lm) or microamperes per lumen. This criterion specifies the number of electrons released by the Photocathode (PC). PC response is always measured in isolation with no amplification stage or ion barrier (film). Therefore, tube data sheets (which always carry this “raw” figure) do not reflect the fact that over 50% of those electrons are lost in the ion barrier. While for most latest 3rd generation image intensifiers the photo response is in the 1800 µA/lm (2000 µA/lm for the latest Omni VI Pinnacle tubes), the actual number is more like 900 µA/lm.

Picatinny Rail/ Mount

- Named after the Picatinny Arsenal in New Jersey, where it was developed, the rail comprises a series of ridges with a T-shaped cross-section interspersed with flat “spacing slots”. Scopes et al. are mounted either by sliding them on from one end or the other; by means of a “rail-grabber” which is clamped to the rail with bolts, thumbscrews or levers; or onto the slots between the raised sections. Picatinny rail sections are the current standard attachment methods for weapon accessories among US and NATO forces.

Resolution

- The ability of an image intensifier or night vision system to distinguish between objects close together. Image intensifier resolution is measured in line pairs per millimeter (lp/mm) while system resolution is measured in cycles per miliradian. For any particular night vision system, the image intensifier resolution will remain constant while the system resolution can be affected by altering the objective or eyepiece optics by adding magnification or relay lenses. Often the resolution in the same night vision device is very different when measured at the centre of the image and at the periphery of the image. This is especially important for devices selected for photograph or video where the entire image resolution is important. Measured in line pairs per millimeter (lp/mm).

Reticle (Reticle Pattern)

- An adjustable aiming point or pattern (i.e. crosshair) located within an optical weapon sight

Signal-to-Noise Ratio (SNR)

- A measure of the light signal reaching the eye divided by the perceived noise as seen by the eye. A tube’s SNR determines the low light resolution of the image tube; therefore, the higher the SNR, the better the ability of the tube to resolve objects with good contrast under low-light conditions. Because SNR is directly related to the photocathode’s sensitivity and also accounts for phosphor efficiency and MCP operating voltage, it is the best single indicator of an image intensifier’s performance

Scintillation

- Also known as electronic noise. A faint, random, sparkling effect throughout the image area. Scintillation is a normal characteristic of Microchannel plate image intensifiers and is more pronounced under low-light-level conditions

Screen

- The image tube output that produces the viewable image. Phosphor (P) is used on the inside surface of the screen to produce the glow, thus producing the picture. Different phosphors are used in image intensifier tubes, depending on manufacturer and tube generation. P-20 phosphor is used in the systems offered in this catalogue

Stereoscopic Night Vision

- When two views or photographs are taken through one device. One view/photograph represents the left eye, and the other the right eye. When the two photographs are viewed in a stereoscopic apparatus, they combine to create a single image with depth and relief. Sometimes this gives two perspectives. However, it is usually not an issue because the object of focus is far enough away for the perspectives to blend into one.

System Gain

- Equal to tube gain minus losses induced by system components such as lenses, beam splitters and filters.

Variable Gain Control

- Allows the user to manually adjust the gain control ( basically like a dim control ) in varying light conditions. This feature sets the PVS-14 apart from other popular monoculars that do not offer this feature.

Weaver Mounting System

- A US weapon mounting system used for attaching sighting devices to weapons. A Weaver Rail is a weapon-unique notched metal rail designed to receive a mating throw-lever or Weaver Squeezer attached to the sighting device

Zeroing

- A method of boresighting an aiming device to a weapon and adjusting to compensate for projectile characteristics at known distances.